TOP > About Us > R&D > High-reliability

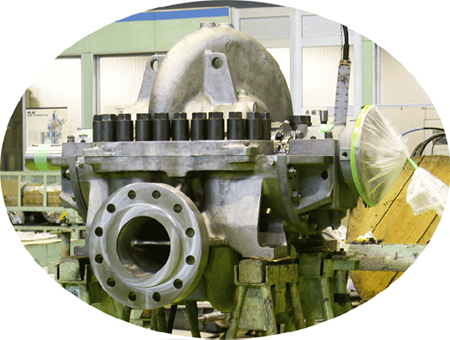

A wide range of pumps are utilized in power and desalination plants, all from which high reliability is demanded to ensure secure and stable plant operation. In order to ensure stable pump performance, factors such as bearing lifespan,

casing pressure, rotor stability and cavitation control, as well as the prevention of corrosion and occurrence of vortices around the suction tank, must all be taken into consideration.

Torishima’s R&D team is striving to conquer these issues through the use of advanced technology in fluid and structural analysis.

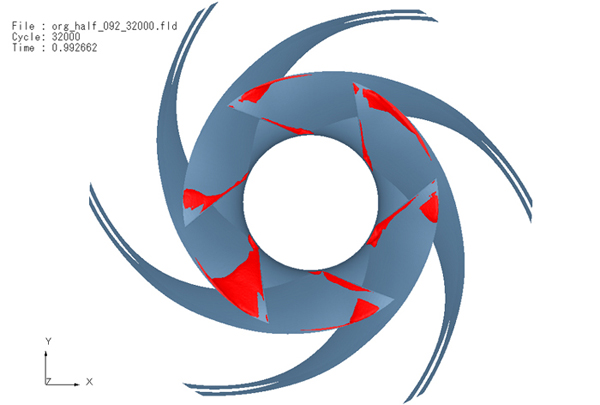

Regulating cavitation is a challenge that must be overcome when realizing both reduced sizes and high speeds in pumps. Using large scale cluster machines and the latest CFD technology, we can predict cavitation development,

which allows us to improve the cavitation characteristics of our products. (Ref. Fig. 1・2).

Fig.1 Results of cavitation analysis

Left:Existing impeller

Right:Improved impeller, the red colored areas indicate vapor phase

Fig.2 Photo of cavitation bubble

(Improved impeller which regulates cavitation)

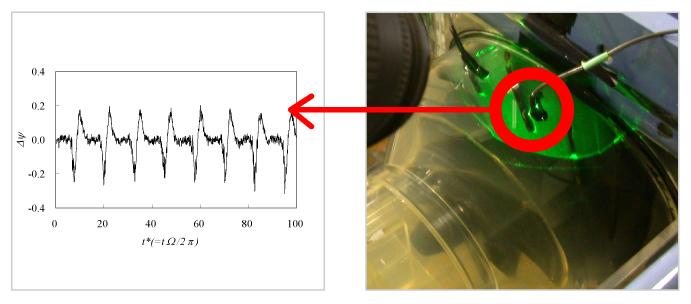

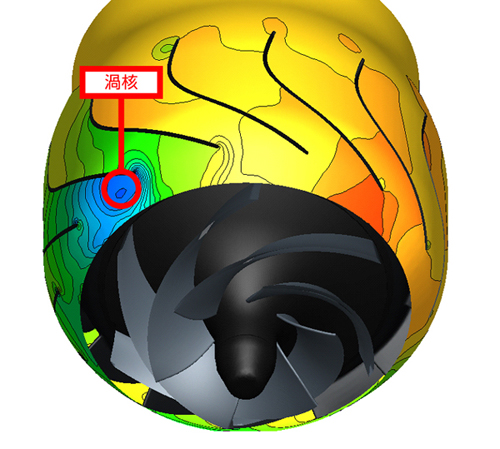

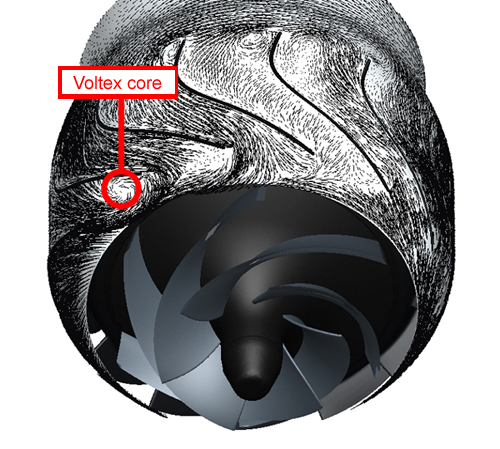

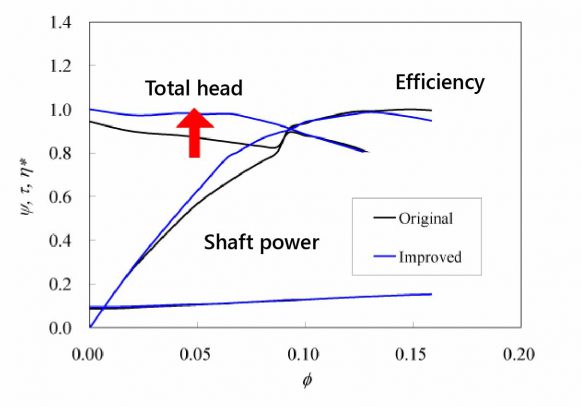

Rotation stalls often happen when flow separation occurs at a partial flow rate due to pressure recovery of the stator vane, etc., of a compact-designed pump. When this happens, the pump operating range is significantly restricted due to the increase in vibration and noise.

In order to investigate the cause of diffuser rotating stalls, the internal flow was measured using a dynamic PIV measurement system.

Moreover, CFD was implemented to clarify the root cause of the diffuser rotating stall. Additionally, a design parameter study was performed on the diffuser to develop conditions in which pump instability characteristics are less likely to occur.

Fig.1 Static pressure fluctuation Fig.2 Measurement area of internal flow and static pressure

Fig.3 Vortec core of a rotating stall(PIV)

Fig.4 Instantaneous static pressure contour map(CFD)

Fig5. Instantaneous velocity vectors(CFD)

Fig.6 Pump performance charactaristics

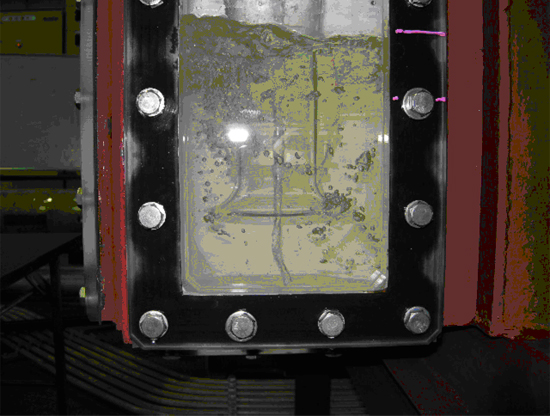

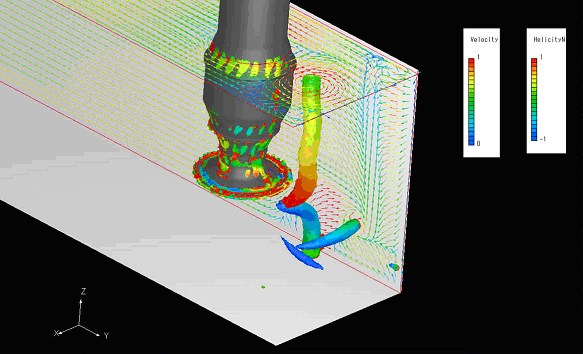

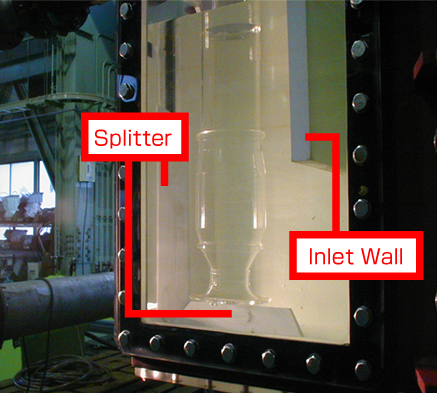

With large-size pumps, if the installation location and the shape of the sump are not adequate, harmful air and submerged vortices occur within the operation of the pump in the suction tank. We are able to predict the occurrence of vortices using a hydraulic model test or CFD (Computational Fluid Dynamics), allowing us to suggest a suitable shape.

Fig.1 Submerged vortex

(sump model test)

Fig.2 Surface vortex

(sump model test)

Fig.3 Vortex prediction

with CFD

Fig.4 Anti-vortex devices

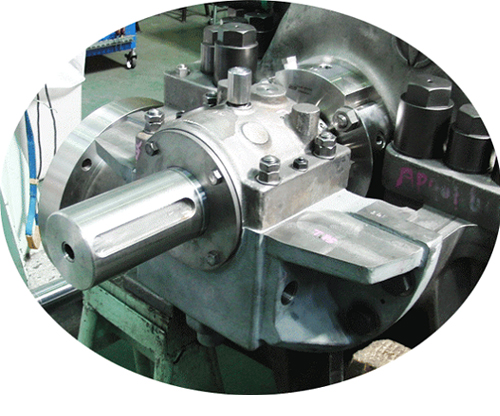

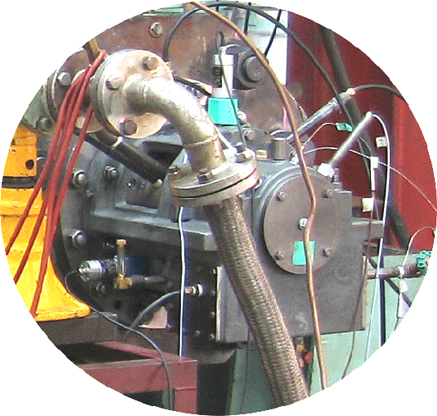

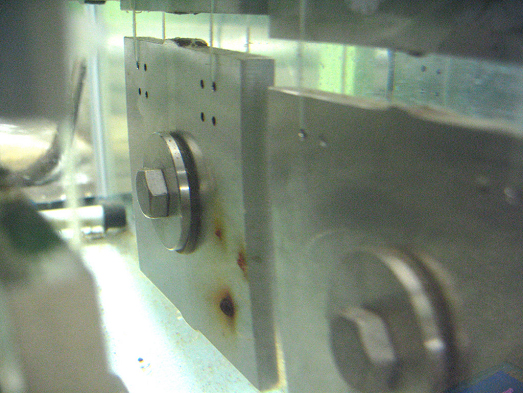

Thanks to optimized bearing design, Torishima Pumps can be maintained and kept running stably for a long time.

By monitoring the vibration of the bearing housing and the rotor bearings, bearing designs can be achieved that stand up against a wealth of operating conditions and environments.

Babbitt journal bearing

Bearing test and diagnosis

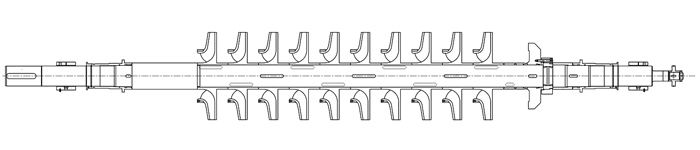

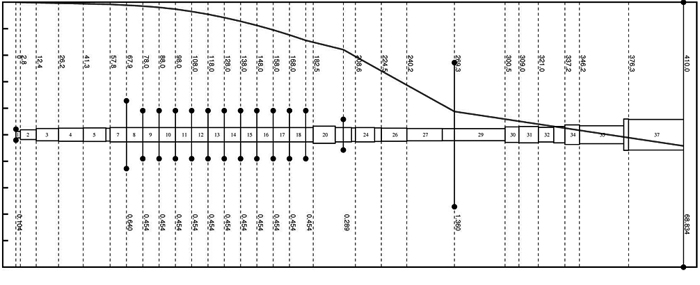

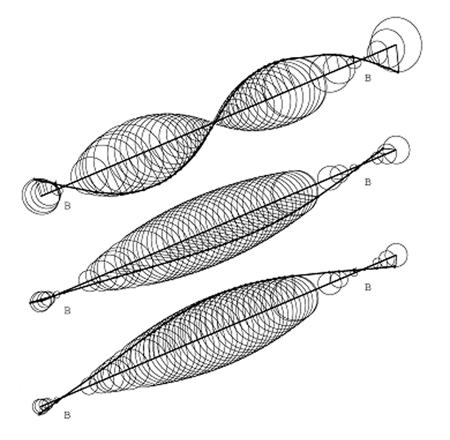

Consideration of the stability of the pump rotor is important when producing safety pumps.

For example (see multi stage high pressure pump : Fig. 1), natural vibration frequency and mode shape (Fig. 2・3) is investigated by using vibration analysis software to perform rotor stability and torsional vibration analysis, even before the pump rotor component is designed.

Fig.1 Structure of multi stage high pressure pump

Fig.3 Results of torsional vibration analysis (natural vibration mode shapes)

Fig.2 Results of rotor stability analysis

(natural vibration mode shapes)

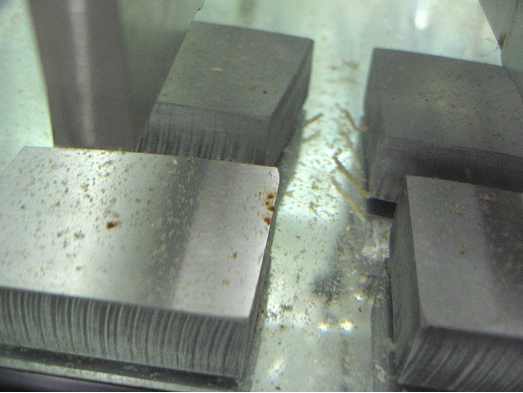

With the increasing demands of sea water pumps, corrosion resistance of the materials used has become more and more important. The elements and temperature of sea water can greatly affect the corrosion resistance of materials, and Torishima carries out corrosion tests according to the sea water conditions of the area to which the pump is delivered. We stand firmly behind our guarantee of reliability.

Corrosion test in seawater

Stainlless-steel RO

high pressure pump

When you visit any website, your browser may store and retrieve information, most commonly through cookies. The information might be about the user, preferences, and device, and is primarily used to make the site function as the user expects. In many cases, this information does not directly identify the user as an individual, but it does allow us to provide you with a more personalized web experience. You can choose not to allow cookies for each cookie category. Click on the heading of each category to learn more and to change the default setting. Please note, however, that blocking some types of cookies may affect the usability of the website and the services we can provide.

These cookies are necessary for the website to function properly and cannot be switched off within the user's system. They are usually only set in response to user actions that correspond to requests for services, such as privacy settings, logging in, filling out forms, etc. You can set your browser to block/warn these cookies, but parts of the site will not work. These cookies do not store any personally identifiable information.

These cookies allow us to count visits and traffic sources to help us measure and improve the performance of our site. They help us to see which pages are most and least popular and to understand how visitors move around the site. All information these cookies collect is combined into a single piece of information, so it remains anonymous. If you do not accept these cookies, we will not know when you visit our site.

We are using cookies to give you the best experience on our website and to analyze our traffic. Please read and agree to our "Use of Cookies" policy. You can also click on [Settings] to customize your cookie settings on our site.