TOP > NEWS > PROJECT HIGHLIGHTS > Enhancing Equipment Reliability and Functionality Through Equipment Renewal in a Drainage Pumping Station

2025.06.18

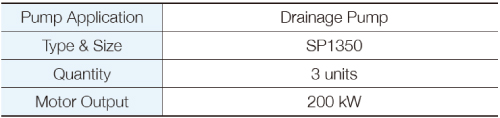

Received an order from Miyazaki Prefecture to maintain pumps and to renovate motors, reducers, and electrical equipment of Obuchi Drainage Pumping Station [Orders Received in March 2025]

Obuchi Drainage Pumping Station is located in the central part of Miyazaki Prefecture, in a nature-rich area with a warm climate. The area is also known for its vegetable production. The plains in the area produce green peppers, tomatoes, cucumbers, cymbidium, and early paddy rice. The highlands are home to livestock, tea leaves, and leaf tobacco. The river-bed and underground water of Hitotsuse River, which runs through the southern region of the town, is rich in minerals, making the region famous for eel aquaculture.

Obuchi Drainage Pumping Station was built in the Waterlogging Prevention Project of FY1988 to protect this frequently-waterlogged area from water damage. As the facility has been in operation for more than 30 years and has deteriorated over time, the number of malfunctions occurring is on the rise. The facility is facing various problems such as discontinuation of some of the equipment and difficulty in getting some of components.

In this construction work, the main pump will be maintained, and accompanying equipment such as the motors and reducers will be updated. The following improvements will also be implemented to de-water the facility and to ease the burden of maintenance and management.

• Pump shaft seal: Gland packing types, which require water injection, will be replaced with waterless mechanical seals.

• Motors: Water-cool types will be replaced with radiator types.

• Reducers: Water-cool types will be replaced with air-cool types.

Changes of external conditions including installation of new greenhouses due to crop switching are worsening the area’s drainage conditions and causing waterlogging again, so we are reinforcing the drainage capacity from 240 m3/min to 250 m3/min per pump. These equipment repairs and renovations will improve the reliability and functionality of the entire facility,

help reduce damage to crops, and protect safety of residents.

When you visit any website, your browser may store and retrieve information, most commonly through cookies. The information might be about the user, preferences, and device, and is primarily used to make the site function as the user expects. In many cases, this information does not directly identify the user as an individual, but it does allow us to provide you with a more personalized web experience. You can choose not to allow cookies for each cookie category. Click on the heading of each category to learn more and to change the default setting. Please note, however, that blocking some types of cookies may affect the usability of the website and the services we can provide.

These cookies are necessary for the website to function properly and cannot be switched off within the user's system. They are usually only set in response to user actions that correspond to requests for services, such as privacy settings, logging in, filling out forms, etc. You can set your browser to block/warn these cookies, but parts of the site will not work. These cookies do not store any personally identifiable information.

These cookies allow us to count visits and traffic sources to help us measure and improve the performance of our site. They help us to see which pages are most and least popular and to understand how visitors move around the site. All information these cookies collect is combined into a single piece of information, so it remains anonymous. If you do not accept these cookies, we will not know when you visit our site.

We are using cookies to give you the best experience on our website and to analyze our traffic. Please read and agree to our "Use of Cookies" policy. You can also click on [Settings] to customize your cookie settings on our site.