Environment

Protecting a Sustainable Planet

Protecting a Sustainable Planet

—Efforts to Address

Climate Change—

With the advance of global warming, the world is now faced with extreme heat waves, frequent torrential

rains, and rising sea levels to the point where it cannot maintain its current state. An international plan,

the Paris Agreement, was adopted in 2016 to “hold the increase in the global average temperature to well

below 2°C above pre-industrial levels and pursue efforts to limit the temperature increase to 1.5°C above

pre-industrial levels.”

In October 2020, Japan also announced its Carbon Neutral Declaration, aiming for decarbonization by 2050.

Torishima, as a socially responsible company, is also working to reduce its environmental impact and address

climate change, both in our business operations and the products and services we provide.

1.Torishima’s initiatives in business operations

At Torishima’s Head Office & Works building located in Takatsuki City, Osaka, we are working to reduce

emissions of (1) carbon dioxide, (2) industrial waste, and (3) Class I Designated Chemical Substances

in our production operations. Regarding resource and energy input, we are monitoring our use of

energy, as converted to crude oil equivalent, and water and working to reduce our consumption of both.

For detailed figures, please refer to

ESG

Data.

Torishima also attained the ZEB Oriented rating standard for our Head Office & Works building, with 100% of the electricity used originating from renewable energy sources.

Since October 2022, Kyushu Torishima, which manufactures Eco-Pumps, has also been using green power for both manufacturing processes and all electricity used in the office. Eco-Pumps are high-efficiency pumps that are distinct from general-purpose pumps, and their basic concept is to contribute to energy efficiency in manufacturing processes by significantly reducing both power consumption and CO2 emissions.

Procuring 100% Renewable Purchased Power

This factory building is powered 100% (approx. 1.25 kWh) by renewable energy sources such as biomass, wind, and solar power generation, which is supplied through the Renewable Energy ECO Plan provided by the Kansai Electric Power Company, Incorporated.

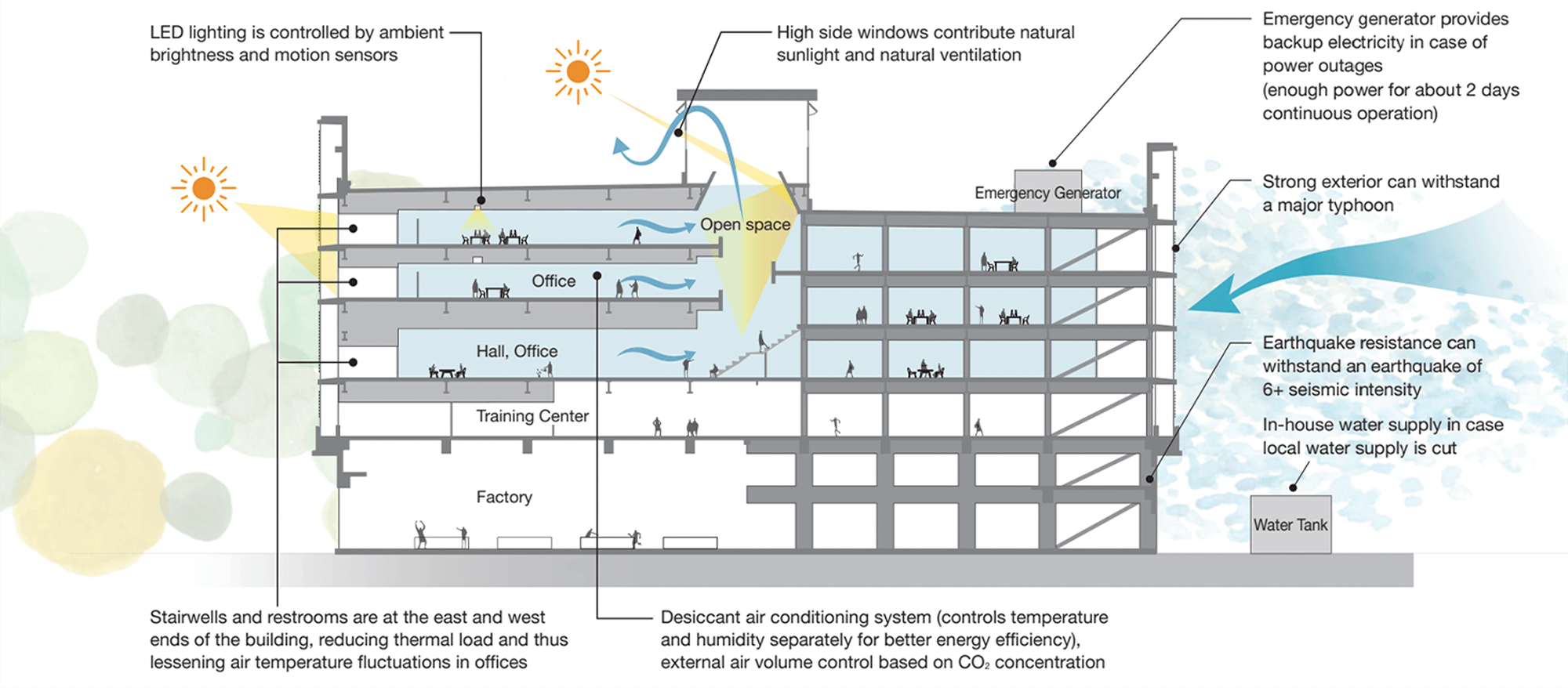

Achieved ZEB Oriented Certification

A ZEB (Net Zero Energy Building) aims to provide a comfortable room environment while also achieving net zero energy consumption for its annual primary energy input and output. With recent developments such as the focus on SDGs (Sustainable Development Goals) and the need to further reduce energy consumption, the definition of ZEB has been expanded to include a new class of building called ZEB Oriented. ZEB Oriented refers to buildings with a total floor area of 10,000 m2 or more that have achieved an energy efficiency rate for their specific application but that use unevaluated technologies. The head office factory uses ingenious ways to reduce energy consumption by more than 40%. It achieves this through building plans such as eaves on the south side and stairwells, restrooms, and storage at the east and west ends of the building where air temperatures fluctuate most. It also adopts state-of-the art technologies such as external air volume control based on CO2 concentration, a natural ventilation system, and a desiccant air conditioning system.

2.Torishima’s initiatives in products and services

“Go Green with Pumps“ initiatives to reduce energy consumption and environmental impact

Pumps play an indispensable role in people’s lives and industrial development, but they also account for a large percentage of energy consumption due to the significant number of units in operation and their operating hours. They reportedly consume about 30% of all electricity used in Japan.

Therefore, we have been carrying out “Go Green with Pumps” initiatives with our Eco-Pumps since fiscal 2009 to communicate that energy consumption can be reduced in pumping operations. In fiscal 2014, Torishima received the Minister of Economic, Trade, and Industry Prize (Business Model Category), the most prestigious award in the Energy Conservation Grand Prize (Product and Business Model Category) for our “Go Green with Pumps” initiatives.

Providing flooding countermeasures, disaster prevention, and mitigation

Climate change has led to frequent heavy rains that cause extensive damage. Torishima’s unique pumping technology helps prepare against the frequent torrential rains caused by extreme weather.

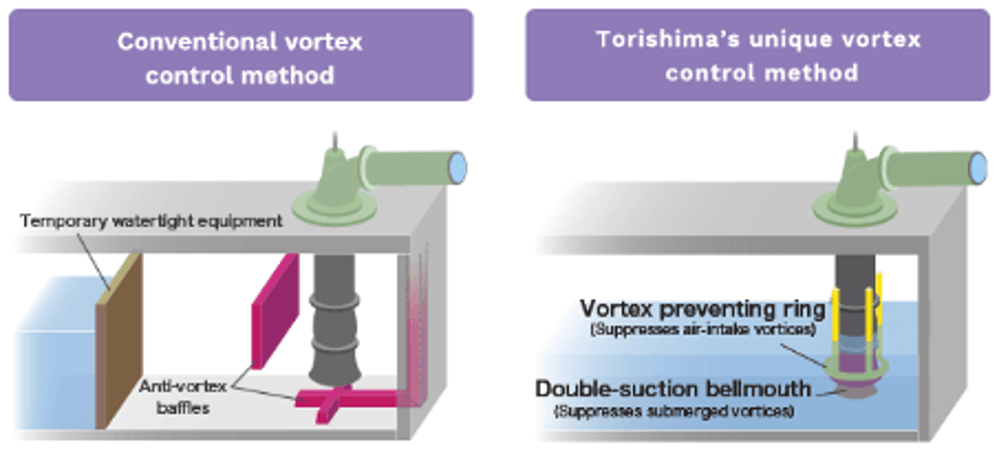

When torrential rain hits, drainage pump stations are subjected to large volumes of rainwater flow over short periods. As a result, more pumps are being replaced or added to increase capacity. However, if pumping volume increases without changing the shape and dimensions of existing pump sumps, the water flow within the sump will increase, causing vortices that can damage the pumps. Torishima’s vortex prevention technology is more effective than conventional anti-vortex baffles (civil engineering) This new technology can suppress vortex within the pump, so it eliminates the need to install the conventional anti-vortex baffles and reduces civil engineering costs.

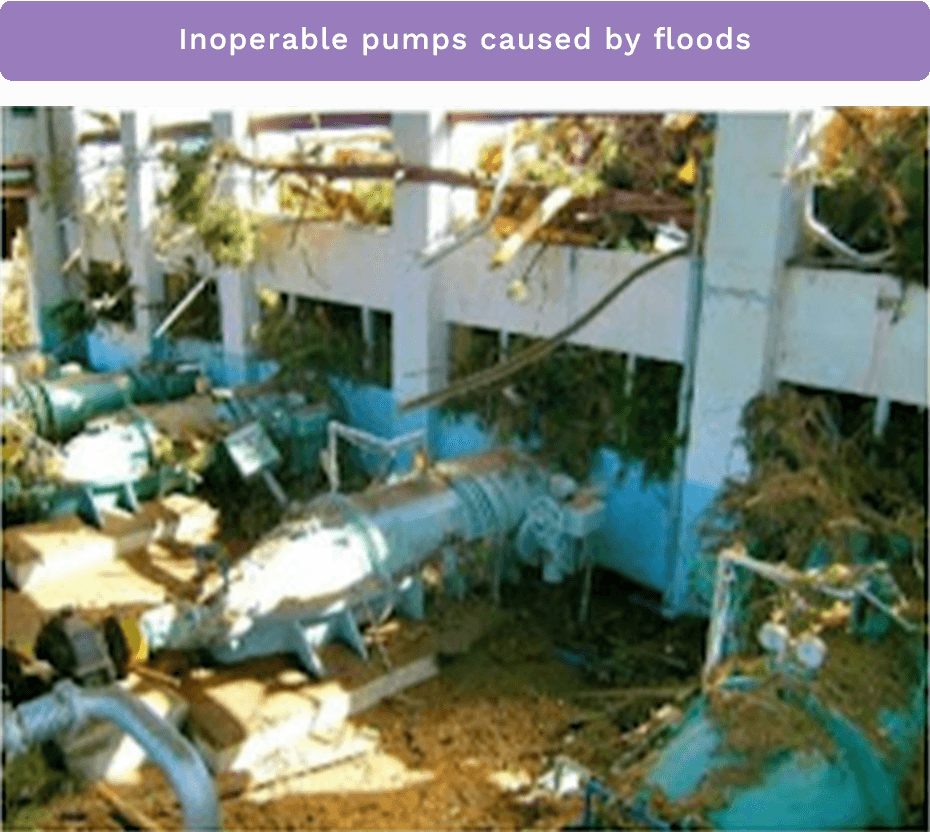

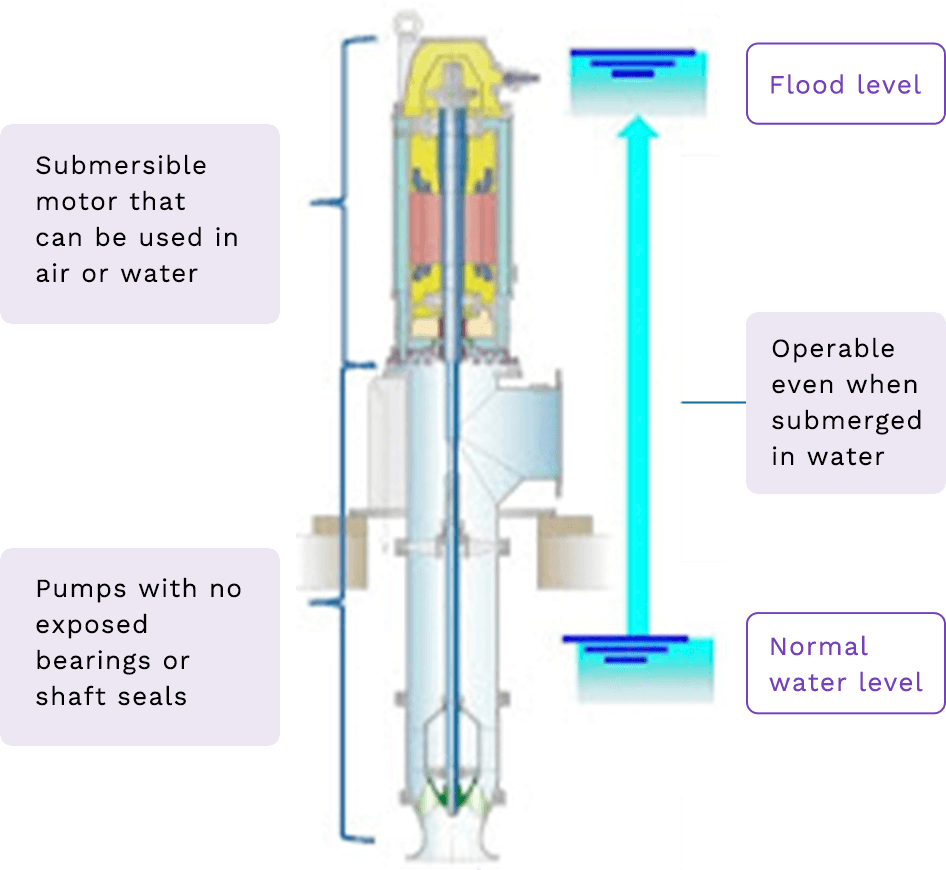

Pump with integrated submersible motor

In recent years, record-breaking torrential rains and large typhoons have flooded pumping stations, rendering pumps inoperable and increasing the damage caused by floods that the stations are meant to protect against. Torishima supplies pump and motor integrated into one unit. Even when flooded, the pumps can operate underwater and continue providing drainage. By integrating the pump and motor into a single unit, installation is simplified and earthquake resistance is improved.

Development of pumps dedicated to ammonia, hydrogen, and other next-generation energy sources

Leveraging our advanced technologies cultivated through the manufacture of pumps for thermal power generation, we also manufacture and supply a large number of pumps for renewable energy applications such as geothermal and biomass power generation, both in Japan and overseas. In particular, boiler feed pumps for biomass power generation are highly competitive, accounting for approximately 90% of the domestic market share.

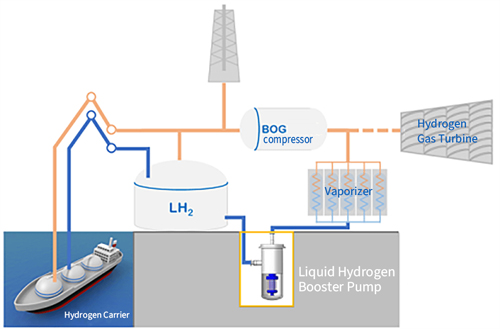

Since FY2021, public and private sectors have been jointly promoting an ammonia co-firing demonstration project as a CO2 reduction technology for thermal power plants, in which Torishima is scheduled to supply pumps. There are high expectations for next-generation energy sources such as ammonia and hydrogen, which do not emit CO2, and large centrifugal pumps play an indispensable role in transporting large volumes of liquefied ammonia/hydrogen. As one of the top manufacturers, Torishima is committed to this mission and plans to conduct Japan’s first performance test of pumps for hydrogen using actual liquids by the end of FY2023.

In June 2023, we proposed “Development of Large-flow, High-pressure, and High-efficiency Liquefied Hydrogen Boosting Pumps” to NEDO’s* “Development of Technologies for Large-scale Hydrogen Supply Chain Establishment” program, which was accepted. We are leading the way by moving forward with full-scale product development for commercialization.

*NEDO: New Energy and Industrial Technology Development Organization

Development of fish-friendly pumps

The European eel has a long history as an edible fish since ancient times, but in recent years it has been listed as an endangered species. While major factors include over-harvesting and disturbance of ecosystems due to industrialization, the population decline is also said to be partly due to eels being sucked into pumps at pumping stations along their migratory route. In response, Torishima has developed a fish-friendly pump with modified impellers that allow eels to swim straight out of the pump even if they are sucked in. As a result, more than 90% of eels sucked into these pump are able to pass through alive.