Society

Work Environment

Safety and Health Policy

Basic Philosophy

Torishima contributes to society through business activities that include the development and manufacture of pumps and related products. At the same time, we regard creating a safe, healthy environment—one where employees can work free of worries and where their health is maintained or even enhanced—as the basis of our QCD (quality, cost, and delivery) actions. We have thus formulated a basic policy on safety and health and are building a culture of safety and health that aims for a virtuous cycle. And we seek to be a vibrant company that continues to grow forever.

Basic Policy

- We are building an occupational safety and health management system based on ISO 45001 and aim to raise the level of safety and health through ongoing improvement activities.

- We identify hazardous factors in the workplace through risk assessments and take countermeasures on an ongoing basis so that we can reduce risks to an absolute minimum.

- We comply with all safety and health-related laws and regulations and company standards in an effort to further our safety and health management.

- We seek to create a comfortable workplace for everyone concerned by ensuring effective communication among Torishima employees and among other people working at Torishima sites.

- We strive to prevent incidents and aim for zero accidents and disasters by raising employees’ awareness of safety and health through education and training.

- In executing safety and health activities, we invest the appropriate management resources and implement effective improvements on an ongoing basis.

1st April, 2022

Kotaro Harada

Representative Director, CEO

Michihiko

Ohie

OHSMS General Manager

ISO45001

Torishima has been certified for the ISO 45001 occupational health and safety management standard so that it can work with employees and other relevant personnel to build a safe work environment.

Improving Health and Safety Standards

As part of our efforts to improve safety and health standards (to prevent industrial accidents at our

factories), Torishima carries out safety patrols, near-miss activities, 5S initiatives, safety and health

education, safety measures based on risk assessments, and in-house safety and health conventions.

Torishima also holds a monthly Partner Company Safety and Health Conference to enhance safety and health

activities with partner companies stationed at the Torishima Head Office & Works building. Our sales offices

also hold District Safety Conferences with partner companies. Working together with our subcontractors, we

are striving to improve our technical expertise and raise awareness of safety and health issues.

Specific initiatives

Near-miss activities

As demonstrated by Heinrich’s Law of 1:29:300, behind every serious accident are 29 minor incidents and 300 near-miss unsafe behaviors and unsafe conditions. In FY2022, initiatives to properly address near-misses were implemented to make risks more visible. Improvements and upgrades have been put in place based on these initiatives, ensuring safer workplaces and improved operations.

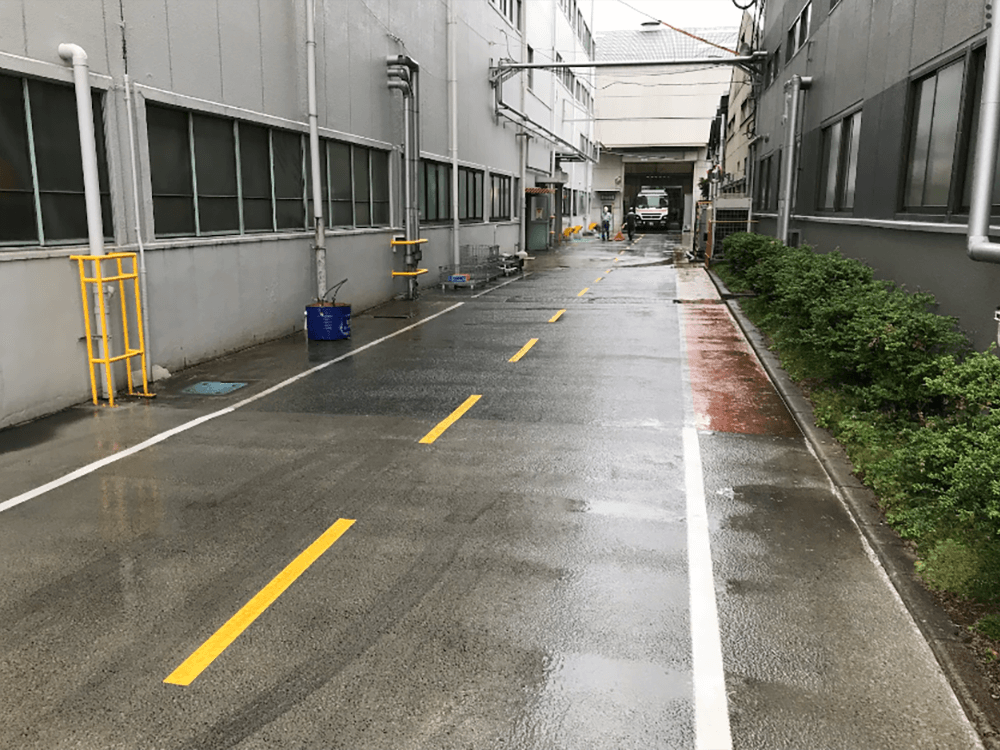

Added centerline to aisle

Before

Frequent near-misses involving collisions occurred

during simultaneous forklift transport operations.

After

Traffic lines for forklifts have been established and they also serve as

guides when backing up trailers, so accidents have been prevented and workability has been

substantially improved.

Safety measures based on risk assessment

Our safety measures are designed to prevent accidents by identifying risks that could lead to hazards or harmful outcomes from factory equipment and operating procedures.

By installing forklift markers, workers can easily see how deep the forks are inserted under the load to prevent the load from collapsing. Illuminating the area around the forklift during operation alert workers in the vicinity, preventing them from coming into contact with the forklift.

Example of forklift safety measures

Protective fences have been installed around assembly robots to prevent contact with workers, and interlocks have been installed to automatically stop machines if the doors are unintentionally opened.

Example of safety measures for processing machinery

Safety and health education

Torishima is committed to improving safety and health standards by implementing not only technical measures, such as maintenance and improvement of equipment and work environments, but also human resource measures, such as acquisition and improvement of skills and knowledge through training, employee education, and awareness programs.

In FY2022, an on-site examination for forklift loading and unloading certificate sponsored by the Land Transportation Safety & Health Association was conducted at the Head Office & Works building. After obtaining the forklift certificate, we continue to set an example of safe operation and improve our instructor skills.

2D code-based health checks and protective equipment inspection records

Torishima has introduced 2D codes that can be scanned with a company-issued smartphone so that health checks and inspection records of protective equipment can be easily and quickly conducted as part of a daily routine.